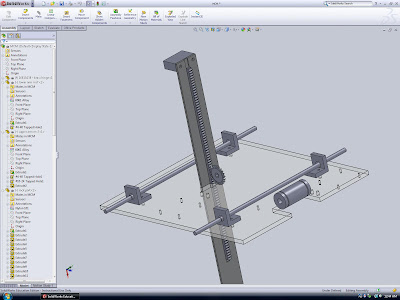

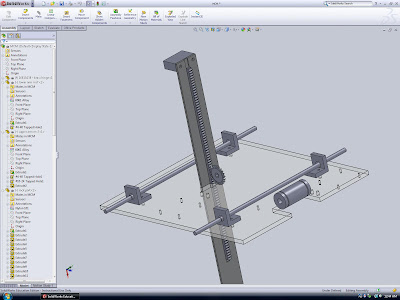

We decided to take off walls and just have a flat platform as our cart. The extra holes visible above are for the motors and the pillow blocks through which the rods that are coupled with the motors will fit through.

We decided to take off walls and just have a flat platform as our cart. The extra holes visible above are for the motors and the pillow blocks through which the rods that are coupled with the motors will fit through.

This week we will finish the manufacturing of all the components to our machine. We have completed majority of the parts but still have a few more things to do. We need to add the grooves to the shafts for the e-clips, drill into the winch and its shaft so that they can be coupled with minimal slipping, and we need to make two more pillow blocks that will be used with the ball bearings on the shaft. We hope to complete the machining of theses parts before lab on Monday so that the machine can be fully assemble by the end of lab. Once we have completed manufacturing, we must assemble all the components to the base plate of the cart. This will be done with screws, nuts and washers. After assembly is complete, we will test out the functionality of our machine with the power source and control systems. We will use the arena to test and fix any problems with the machine before the competition.

ReplyDelete